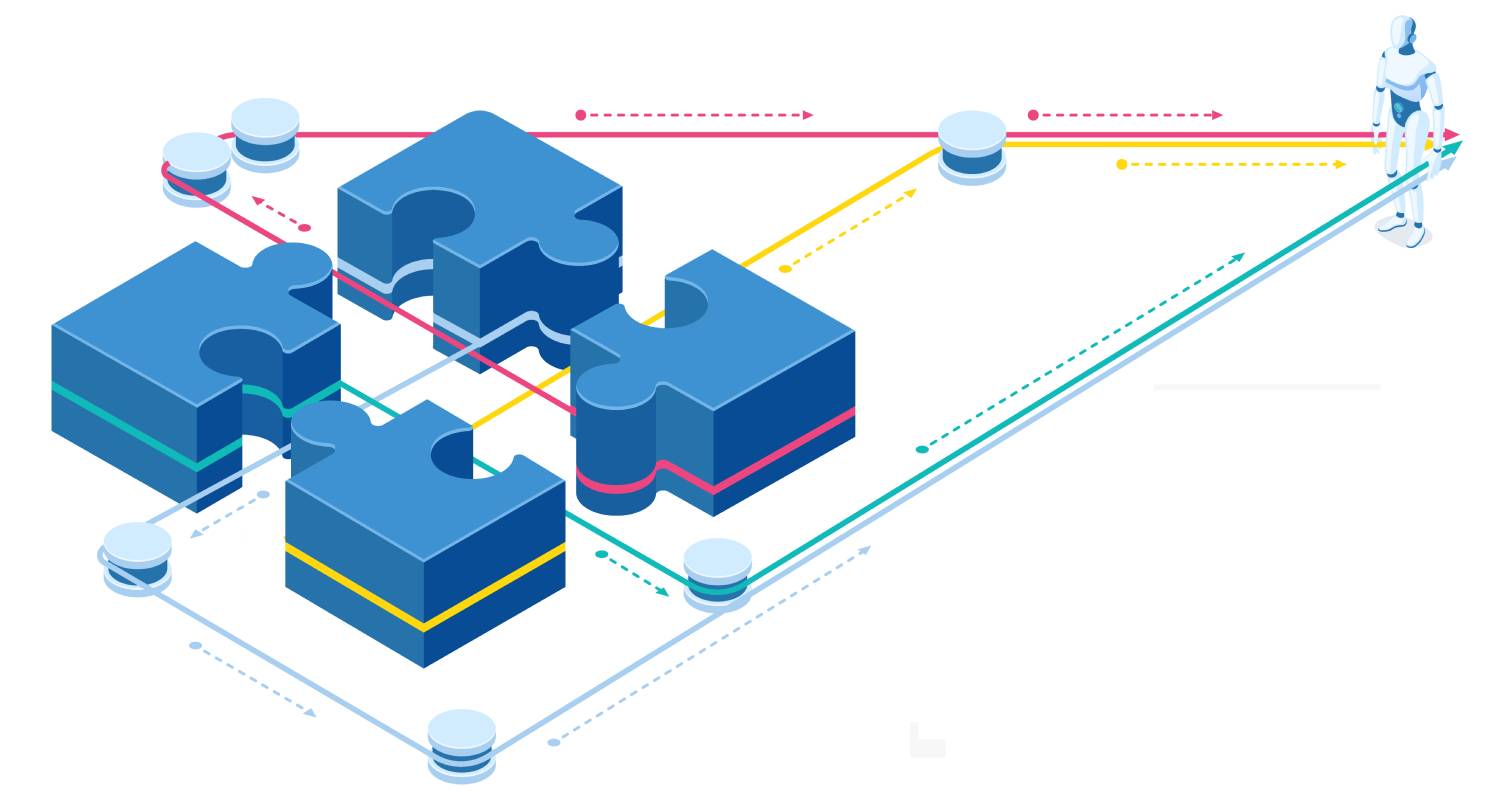

Robot Integration

Robot Integration is the way towards Automation in the industries, peripherals and assembling machinery into a single frame, and work as an one unit. Robot integration enables the industrial robots to perform particular manufacturing task and can bring down expenses, enhance product quality, and decrease cycle time.

Mahajan Automation exceeds expectations at robotic integration and has been giving a large number of automation solutions over the globe. We are prepared to tune in and talk with you about your needs and fulfil your expectations. And give you the ideal Automation Solutions for your Production line.

When you call the specialists at Mahajan Automation, you can hope to be asked the below questions,

for example,

What application do you need automating (material handling, arc welding, drilling)?

What sort of material will you work with?

What are the parts to be handled by the robot now or in the near future?

What is the type of your job and its weight, and which type of application do you need the robot for?

What is the voltage or power supply that will be essential?

Once the essential application requirements are collected and understood, the specialists at Mahajan Automation will offer and help you select the perfect robot to take care of your application. Mahajan Automation takes pride in its capacity to take into account various types of clients and occupations and is centred around enhancing ROI with turnkey automation solutions.

For example, if there was a welding application that required a robotics integration solution, specialists would recommend a robot, alongside any end of arm tooling needs that would suit the application, for example, a welding torch and a welding power source. If it was a material handling application, a specialist would encourage to select or modify the ideal gripper, or if it was a machining application, specialists would help find the correct spindle. Since safety is of most significance when managing integration, Mahajan Automation delegates additional help to figure out additional requirements

for example, automating an entire work cell.

Contingent upon the particular client’s needs, Mahajan Automation can incorporate any part of an automation solution from simply the robot, to the robot and a modified EOAT, to a pre-built or even customized, turnkey work cell. Different robot integration packages are accessible for Mahajan Automation clients with FANUC, KUKA, or ABB robots.

Robot Integration

1. Conceptualizing:

Each reconciliation procedure starts with discussion. Our engineers and staff talk with clients to find out about the particular objectives and requirements for the robot solution and create an outline according to the requirements.

2. Proposition:

Mahajan Automation draws up requirements taking into account that particular client. Robot models, peripherals, work cell designs are proposed in a formal way.

3. Possibility:

Once the essential details of the application and the proposed robot framework are set up, Mahajan automation’s technicians start working according to the requirement.

4. Building:

With the detailed elements of the solution decided, and the robotic integration arrangement thoroughly thought of, mechanical detailed design starts.

5. Establishment:

In the process of Robot Integration, the robot is installed carefully.