Specifications:

About Mahajan Automation

Mahajan Automation is a global leader that collaborates closely with utility, industry, transport, and infrastructure customers in nearly 100 countries. With over four decades of experience, we are at the forefront of digitally connected ABB industrial robotics systems. Our solutions include over 70,000 control systems and 70 million connected devices, helping transform automation on a global scale.

Innovation Through Technology

Staying ahead as a world-class engineering company requires more than just products. Mahajan Automation combines technology leadership, global reach, deep application knowledge, and strong local expertise. We offer a full spectrum of products, systems, and services designed to improve energy efficiency, reliability, and productivity for industrial, utility, and infrastructure sectors.

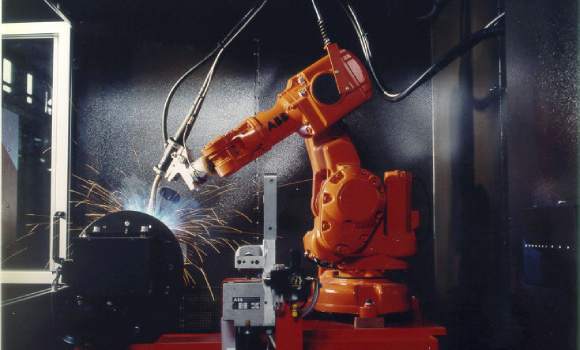

IRB 140 Robot and S4C+ M2000 Controller

The IRB 140 stands out with its integration of the full-sized ABB S4C+ M2000 control cabinet. Unlike many compact robots that lack robust industrial controllers, this setup ensures durability and easy installation in demanding environments.

Though visually similar to the older S4C, the S4C+ M2000 features a powerful PC-based internal system. This upgrade enables enhanced connectivity and far greater processing power than its predecessors. It still retains familiar elements such as servo drives, the RAPID programming language, and the FlexPendant interface.

Built-In Flexibility and I/O Capabilities

A standard configuration includes one I/O card supporting 16 digital inputs and 16 digital outputs. More DI/DO channels or even analog I/Os can be added as needed. The controller also functions as a PLC, managing and monitoring I/O signals in real-time.

Up to three programs can run in parallel—even when the main robot program is paused. Digital outputs can be triggered based on timing or robot positioning. The system includes dual safety circuits (+24V and 0V), eliminating the need for external emergency stops. Additionally, it integrates easily with CAD-CAM systems to generate robot programs from 3D models.

Durable Arm with Versatile Mounting

The IRB 140 arm is fully enclosed with IP67 protection or Class 10 cleanroom certification, making it suitable for harsh environments. Since its introduction in 1999, it has proven highly reliable across various industries.

It offers ±0.03 mm positional repeatability, making it ideal for precision tasks. The IRB 140 also provides excellent path accuracy and can be mounted at virtually any angle—floor, wall, ceiling, or tilted—maximizing its reach and adaptability.

| Robot Information | |||||

|---|---|---|---|---|---|

| Specifications | Motion Speed | Motion Range | |||

| Axes: | 6 | J1 | 200 °/s (3.49 rad/s) | J1 | ±360° |

| Payload: | 6.00kg | J2 | 200 °/s (3.49 rad/s) | J2 | ±200° |

| H-Reach: | 810.00mm | J3 | 260 °/s (4.54 rad/s) | J3 | ±280° |

| Repeatability: | ±0.0300mm | J4 | 360 °/s (6.28 rad/s) | J4 | ±4 00° |

| Robot Mass: | 98.00kg | J5 | 360 °/s (6.28 rad/s) | J5 | ±240° |

| Structure: | Articulated | J6 | 450 °/s (7.85 rad/s) | J6 | ±800° |

| Mounting: | Floor | ||||