Robotic Food Industry Vision System

Looking for a Robotic Food Industry Vision System that delivers accurate inspection, sorting, and quality control? Our intelligent vision solutions ensure superior food safety, consistent quality, and higher productivity through hygienic, automated processes. Get in touch today to upgrade your food production with smart vision automation.

Robotic Food Industry Vision Sytem

Robotic Food Industry Vision Systems deliver high-precision inspection, guidance, and quality control for automated food processing and packaging lines. Powered by advanced machine vision, AI-based image processing, and real-time analytics, these systems accurately detect defects, verify size, shape, color, orientation, and ensure food safety compliance. Integrated with robotic automation, they enable vision-guided picking, sorting, grading, portioning, and packaging of fresh, frozen, and packaged foods. With enhanced traceability, reduced contamination risk, improved consistency, and higher throughput, robotic food vision systems optimize production efficiency while meeting strict hygiene standards and regulatory requirements in modern food manufacturing environments.

Robotic Food Industry Vision System Applications

Automated Food Inspection & Quality Control

Vision-guided robotic systems inspect food products for size, shape, color, surface defects, contamination, and foreign objects. Using machine vision inspection, AI vision sensors, and real-time image processing, the system ensures consistent food quality, reduces rejects, and complies with food safety standards.

Vision-Based Sorting & Grading

Used for sorting fruits, vegetables, bakery items, meat, seafood, and packaged foods based on quality parameters. Robotic vision systems, camera-guided robots, and smart food sorting automation improve throughput, eliminate manual errors, and maintain uniform grading at high speeds.

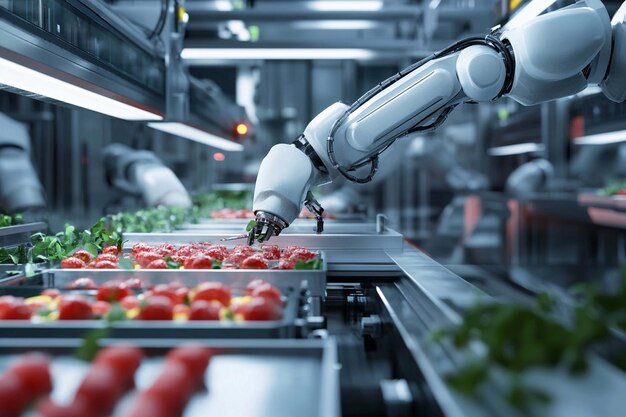

Pick-and-Place & Packaging Automation

Integrated vision systems guide robots to accurately pick randomly oriented food items and place them into trays, cartons, or packaging lines. Vision-guided robotic picking, food packaging automation, and hygienic robotic handling enable high-speed, contamination-free operations.

Label Verification & Traceability Inspection

Vision systems verify barcodes, expiry dates, batch numbers, seal integrity, and label alignment on food packages. Automated label inspection, barcode verification systems, and traceability automation help food manufacturers meet regulatory compliance and reduce recalls.

Robotic Food Industry Vision System Applications

Pick-and-Place & Packaging Automation

Integrated vision systems guide robots to accurately pick randomly oriented food items and place them into trays, cartons, or packaging lines. Vision-guided robotic picking, food packaging automation, and hygienic robotic handling enable high-speed, contamination-free operations.

Label Verification & Traceability Inspection

Vision systems verify barcodes, expiry dates, batch numbers, seal integrity, and label alignment on food packages. Automated label inspection, barcode verification systems, and traceability automation help food manufacturers meet regulatory compliance and reduce recalls.

Pick-and-Place & Packaging Automation

Integrated vision systems guide robots to accurately pick randomly oriented food items and place them into trays, cartons, or packaging lines. Vision-guided robotic picking, food packaging automation, and hygienic robotic handling enable high-speed, contamination-free operations.

Label Verification & Traceability Inspection

Vision systems verify barcodes, expiry dates, batch numbers, seal integrity, and label alignment on food packages. Automated label inspection, barcode verification systems, and traceability automation help food manufacturers meet regulatory compliance and reduce recalls.

Benefits of Robotic Food Industry Vision System

Enhanced Quality Inspection & Food Safety

Robotic food vision systems enable automated visual inspection, detecting defects, contamination, shape irregularities, and foreign objects with high accuracy. This improves food quality control, ensures food safety compliance, and reduces the risk of recalls.

High-Speed Sorting & Grading Accuracy

Using machine vision cameras, AI-based image processing, and deep learning algorithms, robotic systems perform rapid food sorting, grading, and classification based on size, color, texture, and weight—maintaining consistency even at high production speeds.

Reduced Manual Intervention & Labor Costs

Automation minimizes reliance on human inspection, reducing labor dependency, operator fatigue, and human error. Vision-guided robots ensure consistent inspection performance across long shifts in food processing lines.

Improved Traceability & Process Control

Integrated with PLC, SCADA, and MES systems, food vision solutions support real-time monitoring, data logging, and traceability. This enables better process optimization, compliance with HACCP, ISO, and global food industry standards.

Hygienic, Non-Contact & Flexible Operation

Robotic vision systems provide non-contact inspection, ideal for hygienic food environments. They adapt easily to multiple food products, packaging formats, and production lines, making them suitable for fresh produce, bakery, dairy, meat, seafood, and packaged food applications.