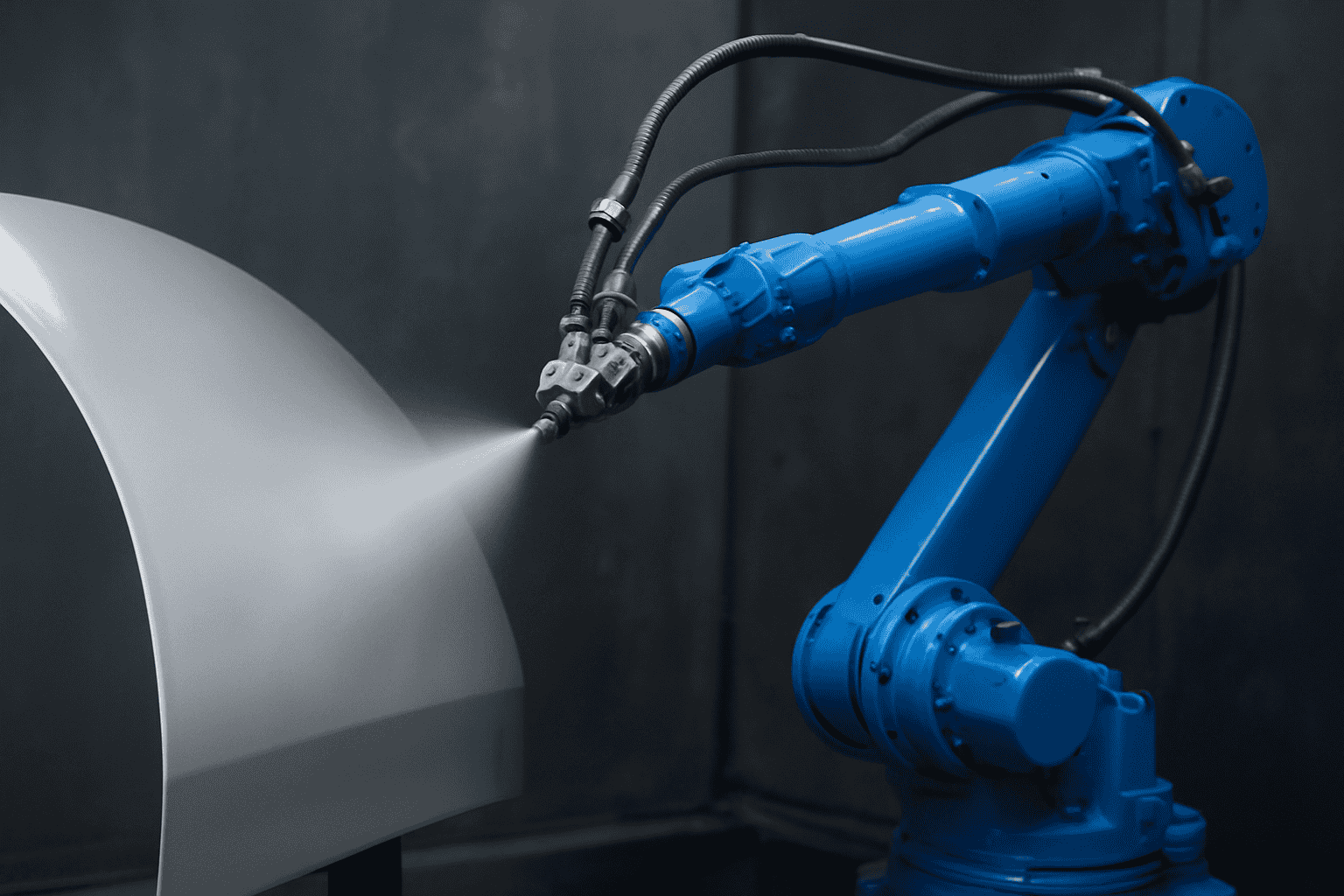

Robotic Spray Painting/Coating System

Looking for a Robotic Spray Painting / Coating System that delivers uniform coverage, superior finish quality, and repeatable results? Our advanced robotic spray painting and automated coating systems ensure precise paint deposition, consistent film thickness, and flawless surface finishes across every component. Designed to reduce overspray, material waste, and rework, these systems significantly improve productivity while maintaining strict quality standards. Trusted by leading automotive, manufacturing, and industrial brands worldwide, we bring efficiency, consistency, and cost control to every coating operation. Get in touch today and elevate your surface finishing to the next level.

Robotic Spray Painting Coating System

Robotic Spray Painting and Coating Systems provide fast, precise, and uniform surface finishing with consistent coating quality across complex parts. These automated systems reduce overspray, improve material efficiency, enhance safety, and deliver high-quality finishes for high-volume and precision-driven manufacturing applications.

Robotic Spray Painting & Coating System

Spray Painting & Coating Systems utilize advanced robotic automation to deliver precise, uniform, and high-quality paint application across a wide range of industrial surfaces. Using intelligent spray guns and programmable motion control, these systems ensure consistent coating thickness, superior adhesion, and flawless surface finishes while minimizing overspray and material waste.

Designed for high-production environments, automated spray coating improves transfer efficiency, reduces operational costs, and enhances product durability. The technology supports complex geometries and hard-to-reach areas with exceptional accuracy, making it ideal for manufacturers seeking reliable and repeatable finishing results.

By reducing manual involvement, robotic spray painting also promotes safer working conditions by limiting exposure to fumes and hazardous chemicals. This smart automation solution helps industries achieve faster production cycles, improved quality standards, and long-term performance — making it a critical component of modern manufacturing facilities.

Types of Liquid Paint Dispensing

Air Spray Technology

Uses compressed air to atomize liquid paint into fine droplets, delivering smooth and even coverage. Ideal for applications requiring high-quality decorative finishes.

Airless Spray Technology

Pumps paint at high pressure without compressed air, producing a uniform coating with higher transfer efficiency and reduced overspray. Perfect for large surfaces and heavy-duty coatings.

Electrostatic Spray Coating

Applies an electrical charge to paint particles, attracting them directly to grounded surfaces. This method maximizes paint utilization, reduces waste, and ensures a highly consistent finish.

HVLP High Volume Low Pressure Spray

Applies an electrical charge to paint particles, attracting them directly to grounded surfaces. This method maximizes paint utilization, reduces waste, and ensures a highly consistent finish.

Automated Robotic Spray Systems

Integrates industrial robots with smart spray controls to maintain precise distance, angle, and flow rate — ensuring repeatable quality and faster production speeds.

Automated Robotic Liquid Paint Dispensing

Automated robotic liquid paint dispensing uses advanced spray technology and intelligent motion control to apply precise and consistent paint coatings on industrial surfaces.

Robotic Spray Painting / Coating Systems Application's

Automotive Body & Chassis Welding

Robotic laser welding is widely used in automotive manufacturing for body panels and chassis parts. It delivers high-speed, precise welds with minimal distortion, ensuring strong and lightweight vehicle structures.

Precision Sheet Metal Fabrication

Laser welding is ideal for thin and complex sheet metal components. It provides clean, accurate welds with excellent finish, reducing the need for post-processing.

Aerospace & Aviation Components

TIG welding is preferred in aerospace industries for its superior precision and clean weld quality. It is ideal for critical components where strength and accuracy are essential.

Precision Sheet Metal Fabrication

TIG welding is commonly used for stainless steel and aluminum parts. It produces smooth, high-quality welds with excellent control and minimal contamination.

Heavy Structural & Industrial Fabrication

MIG welding is widely used for welding thick materials and structural components. Its high deposition rate ensures strong joints and faster production.

Automotive & Mass Production Welding

MIG welding supports high-volume manufacturing with consistent weld quality. It is efficient, cost-effective, and suitable for repetitive welding tasks.

Benefits of Robotic Spray Painting / Coating Systems

Uniform coating

Robotic spray painting systems deliver consistent film thickness, smooth surface finish, and precise coverage on every part. Automated path control eliminates streaks, overspray variation, and human inconsistency—ensuring premium-quality results.

reduced overspray

Robots operate at optimized speeds with repeatable motion, significantly reducing cycle time. Continuous operation enables high-volume production with predictable output and minimal downtime.

high-speed production

Precise spray control and optimized atomization minimize overspray and material loss. This leads to lower paint consumption, reduced rework, and significant cost savings on coatings and consumables.

Improved Worker Safety & Environmental Compliance

Robotic systems reduce operator exposure to hazardous fumes, solvents, and airborne particles. They also support controlled booth environments and compliance with environmental and workplace safety regulations.

Flexibility Across Parts, Materials & Coatings

Robotic spray painting systems can handle complex geometries and support various coatings—such as liquid paint, powder coating, primers, sealants, and protective finishes—across industries including automotive, aerospace, appliances, furniture, and general manufacturing.

Frequently Asked Questions FAQ

What is a Robotic Spray Painting / Coating System?

A Robotic Spray Painting or Coating System is an automated solution where industrial robots perform paint or protective coating applications with high precision and uniform coverage. It ensures consistent film thickness, reduced overspray, and improved surface finish in automotive, industrial, and manufacturing applications.

What are the advantages of a Robotic Spray Painting System?

A robotic spray painting system improves coating consistency, reduces material waste, and increases production speed. It enhances workplace safety by limiting human exposure to fumes and hazardous materials while delivering superior surface quality and repeatable results.

What is Robotic Investment Casting and where is it used?

Robotic Investment Casting, also known as lost-wax casting, uses automated systems to handle wax pattern assembly, ceramic shell building, and metal pouring. It is widely used for producing complex, high-precision components in aerospace, medical equipment, and engineering industries due to its excellent detail and surface finish.

Which industries use Robotic Coating Systems?

Robotic coating systems are widely used in automotive manufacturing, heavy machinery, consumer appliances, metal fabrication, aerospace components, and industrial equipment production. They are ideal for high-volume production lines requiring uniform paint or protective coating application.

Why choose a Robotic Spray Painting / Coating System over manual painting?

Choosing a robotic spray painting system increases productivity, reduces rework, and ensures consistent quality across batches. It lowers operational costs over time, improves efficiency, and delivers precise, automated coating solutions for modern industrial manufacturing environments.